Hydracooling

José Carlos

Line

João Jordão

Development

Toni Silva

Line

Ricardo Vieira

Injection

Paulo Pereira

Metalworking

João Vieira

Production

Eduardo Oliveira

Board

Rui Carmo

Development

Carlos Alberto

Preparations

Rogério Zeferino

Preparations

João Correia

Development

Isabel Nogueira

Commercial

Filipe Castro

Preparations

Jerónimo Teixeira

Preparations

Henrique Santos

Development

Francisco Mora

Preparations

Pedro Barroso

Logistic

Jonisson Nascimento

Metalworking

Elisabete Gonçalves

Line

Rui Magalhães

Metalworking

Dinis Matos

Thermoforming

José Ribeiro

Quality

Fábio Ferreira

Line

Hugo Silva

Line

Liliana Vieira

Human Resources

Luis Ribeiro

Development

Celso Castro

Development

Francisco Sousa

Line

Vítor Barbosa

Preparations

Abel Ferreira

Metalworking

Paulo Correia

Metalworking

Rita Ribeiro

Communication

Fernando Martins

Production

Ângela Nunes

Development

Renato Pereira

Metalworking

Guilherme Bezerra

Injection

Diogo Silva

Line

Nelson Ribeiro

Thermoforming

Raúl Ferreira

Line

Ricardo Fernandes

Metalworking

Ana Almeida

Production

Elsa Faria

Accounting

Rui Sousa

Line

Marco Paulo

Logistic

Maria Cunha

Communication

Benigno Júnior

Injection

Paulo Guimarães

Metalworking

José Peixoto

Maintenance

Joaquim Ribeiro

Logistic

Daniel Dias

Development

Diogo Couceiro

Marketing

Bibiana Coelho

Purchasing

Vítor Macedo

Preparations

Bruno Ferreira

Metalworking

Metalworking

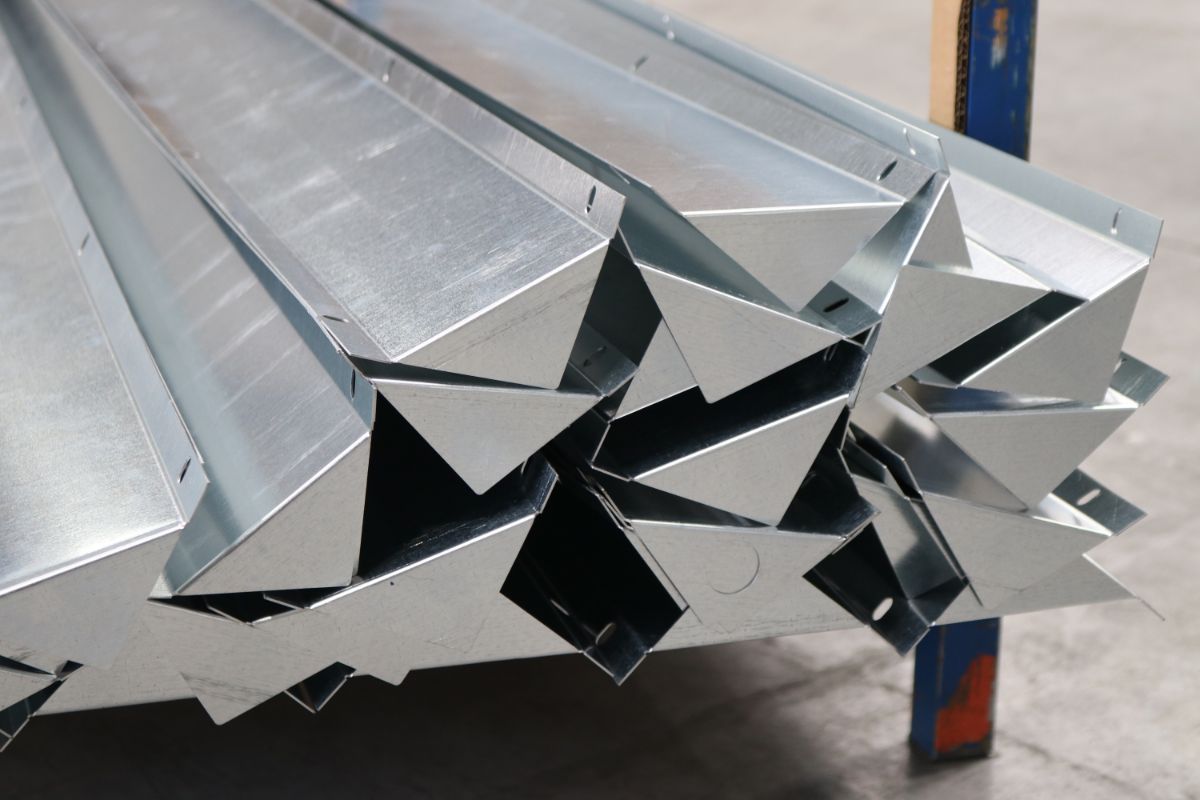

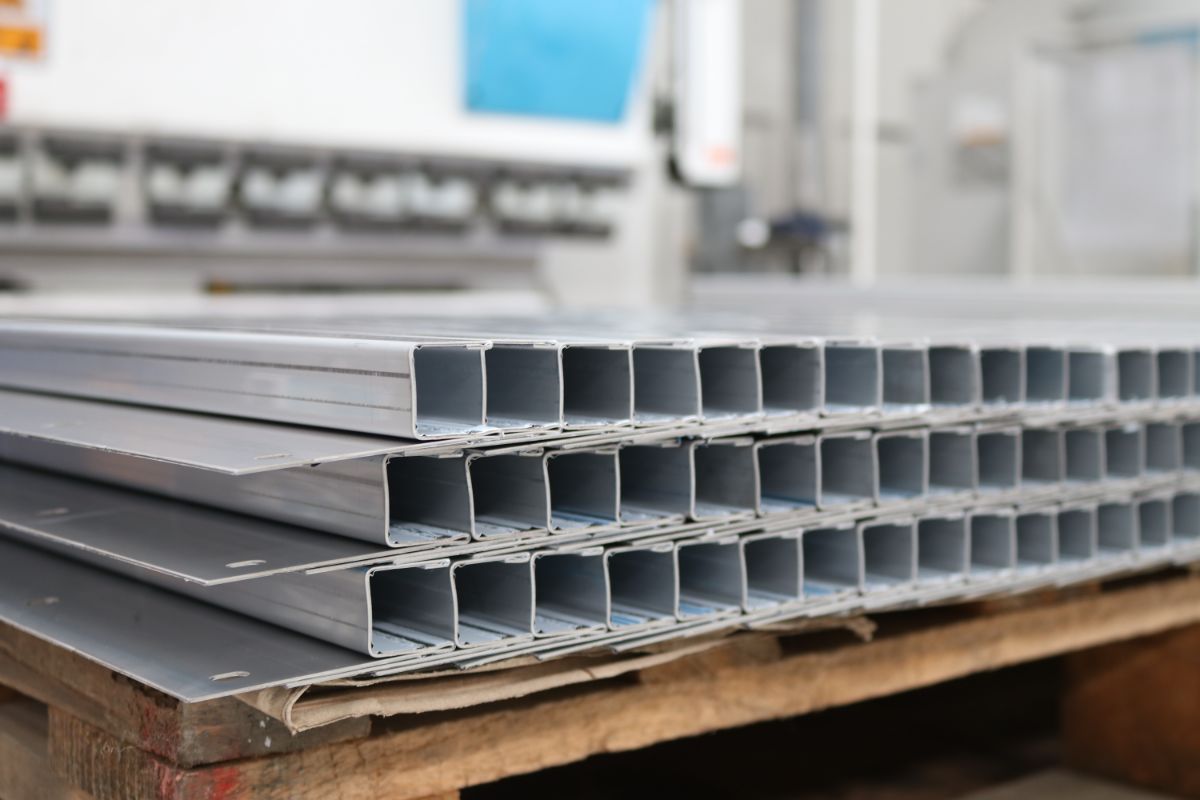

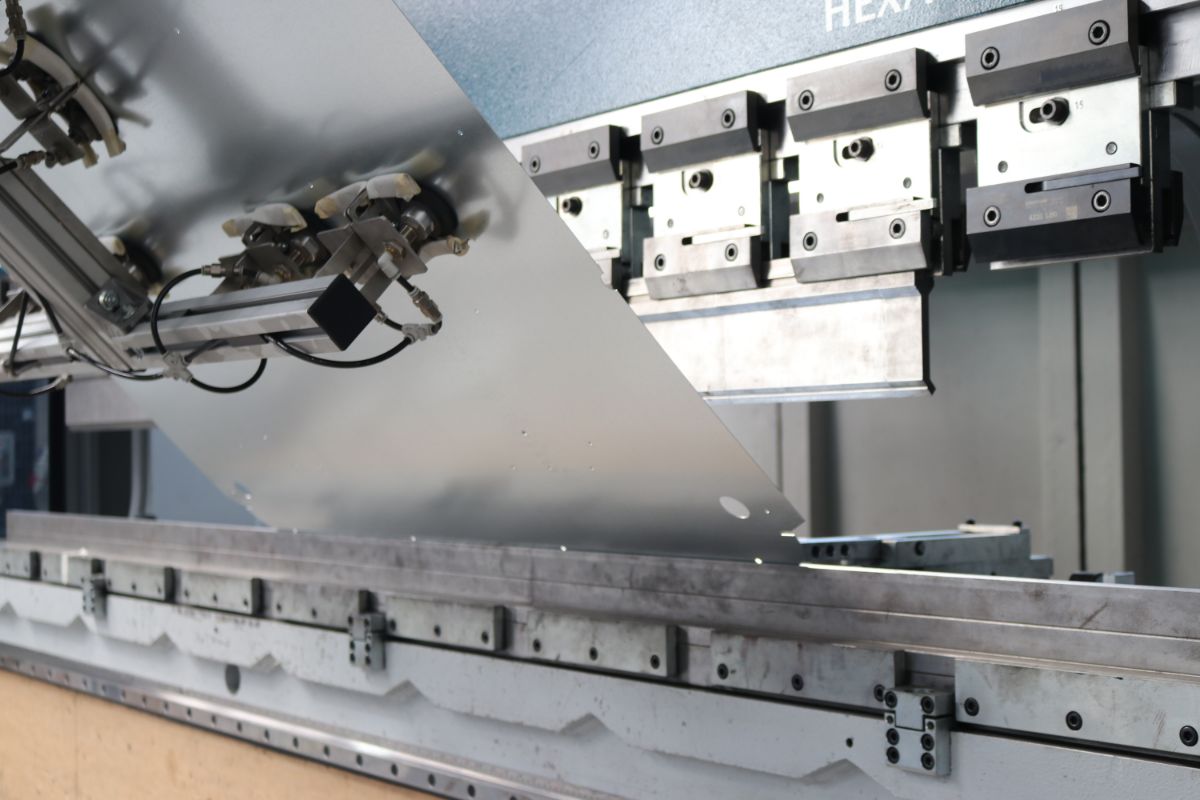

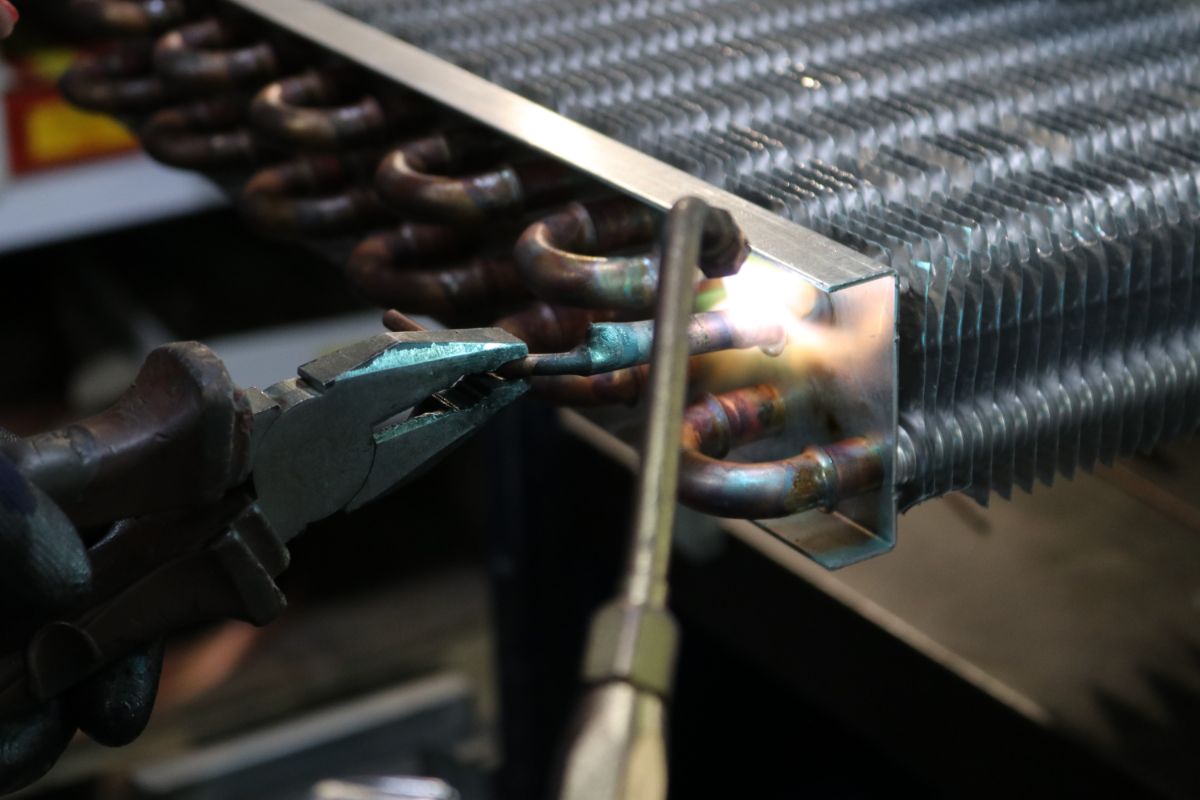

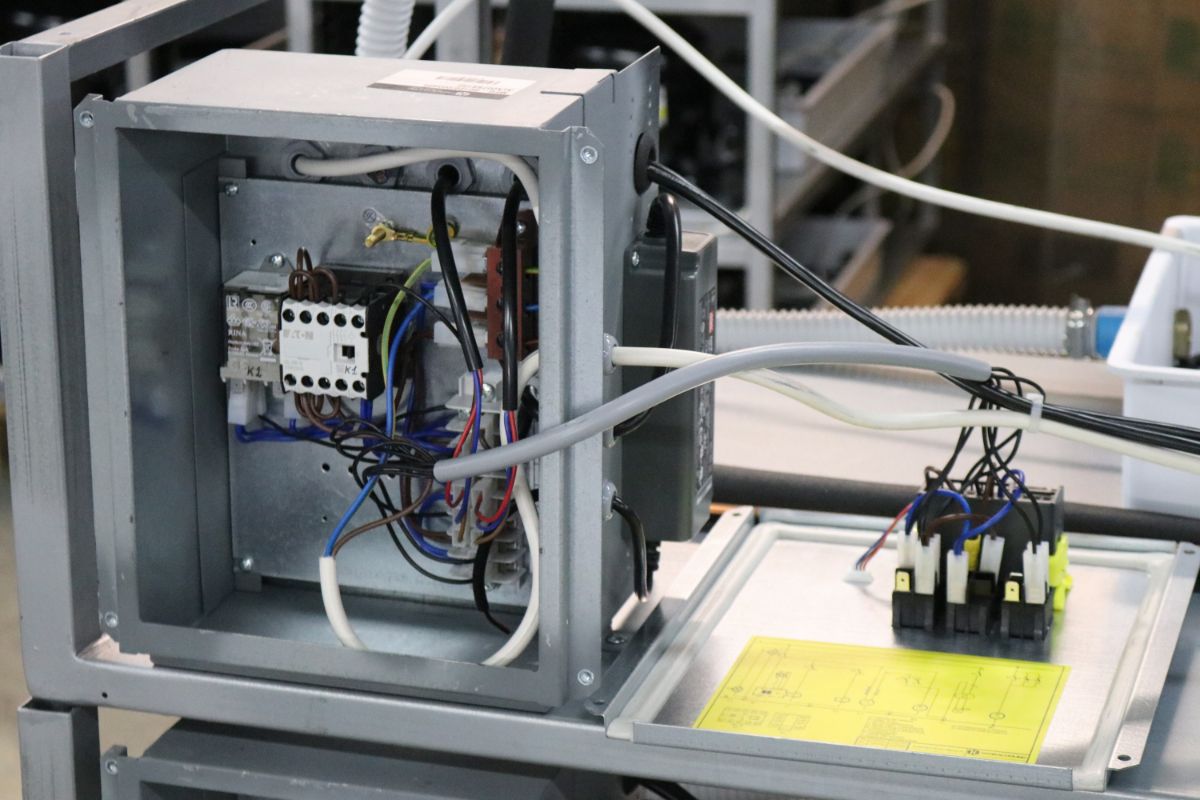

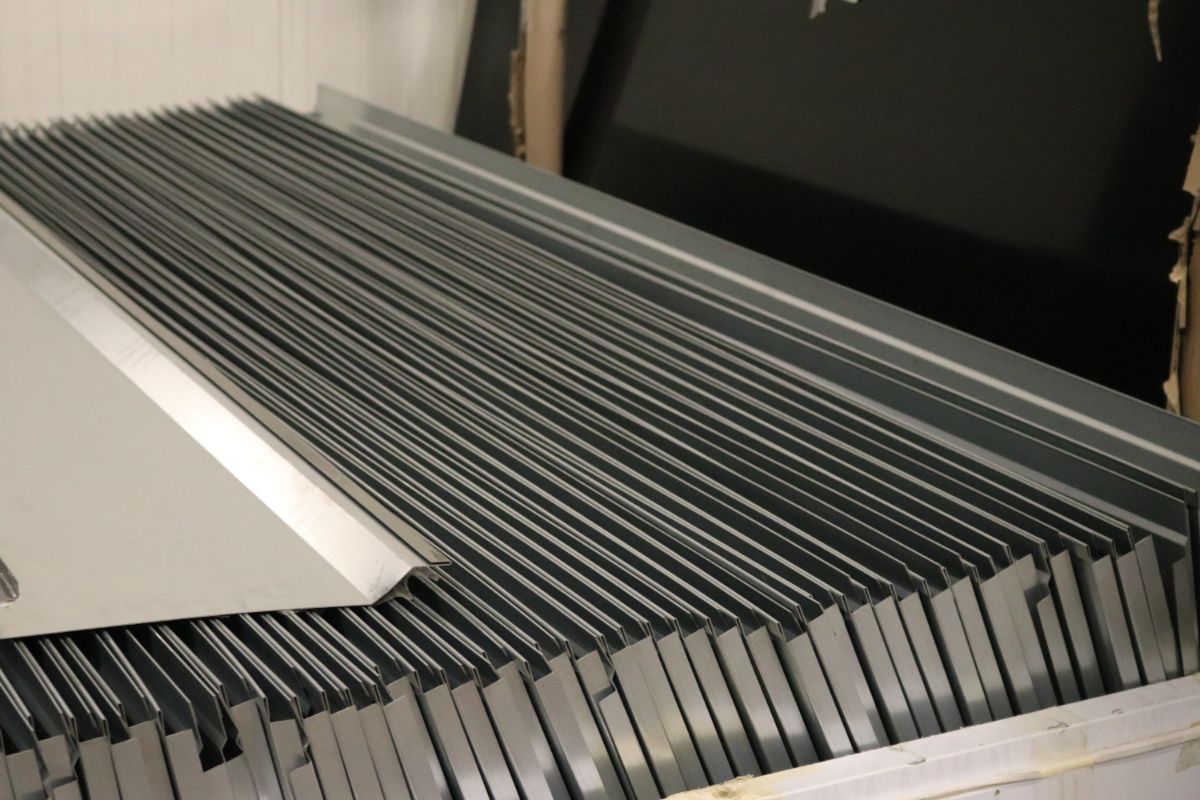

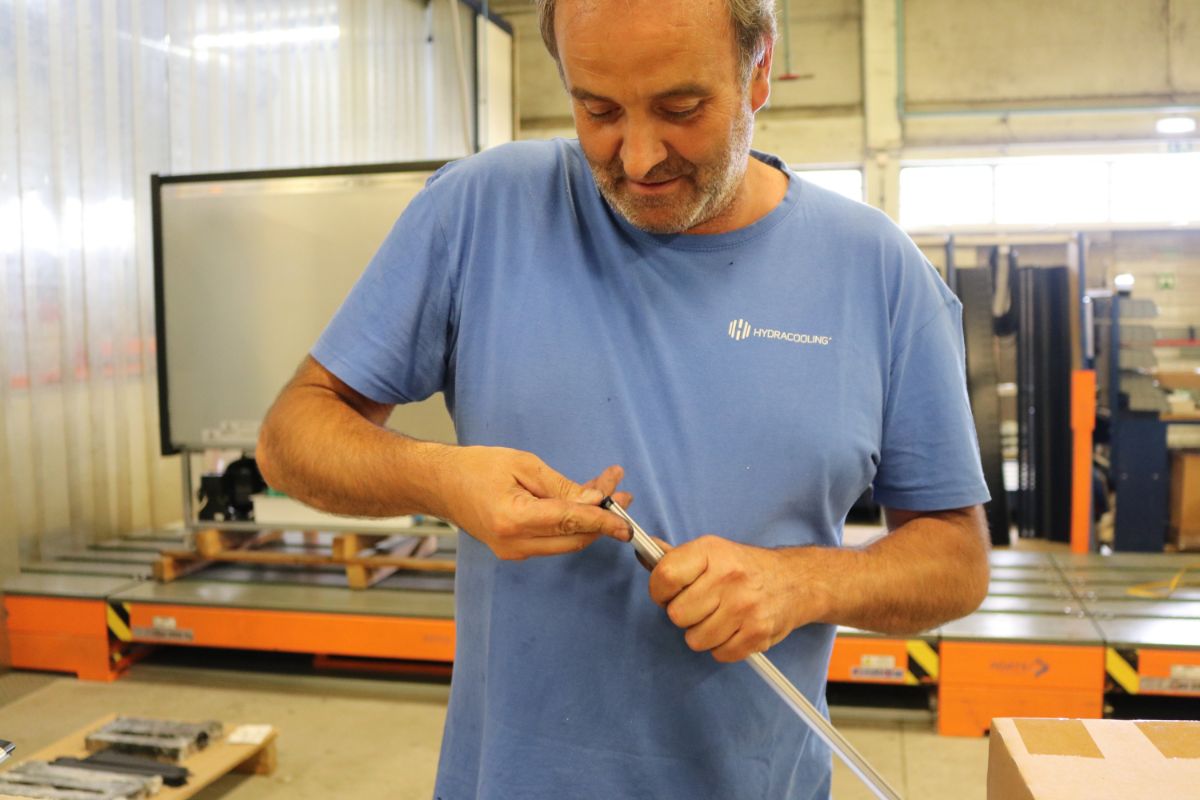

Oriented towards industry 4.0, Hydracooling has a technology park allowing it to improve efficiency and productivity.

Thanks to an automatic folding robot, the company seeks to maximize the quality-cost-benefit relationship without forgetting product quality and safety. The process is automatic and autonomous in synchronization with the steel folder, without the need for any intervention by the worker.

Hydracooling has integrated various technologies into its industrial automation and owns a laser cutting machine and a punching machine, both with automatic loading and unloading, thus allowing an acceleration of the process thanks to the continuous processing.

Preparations

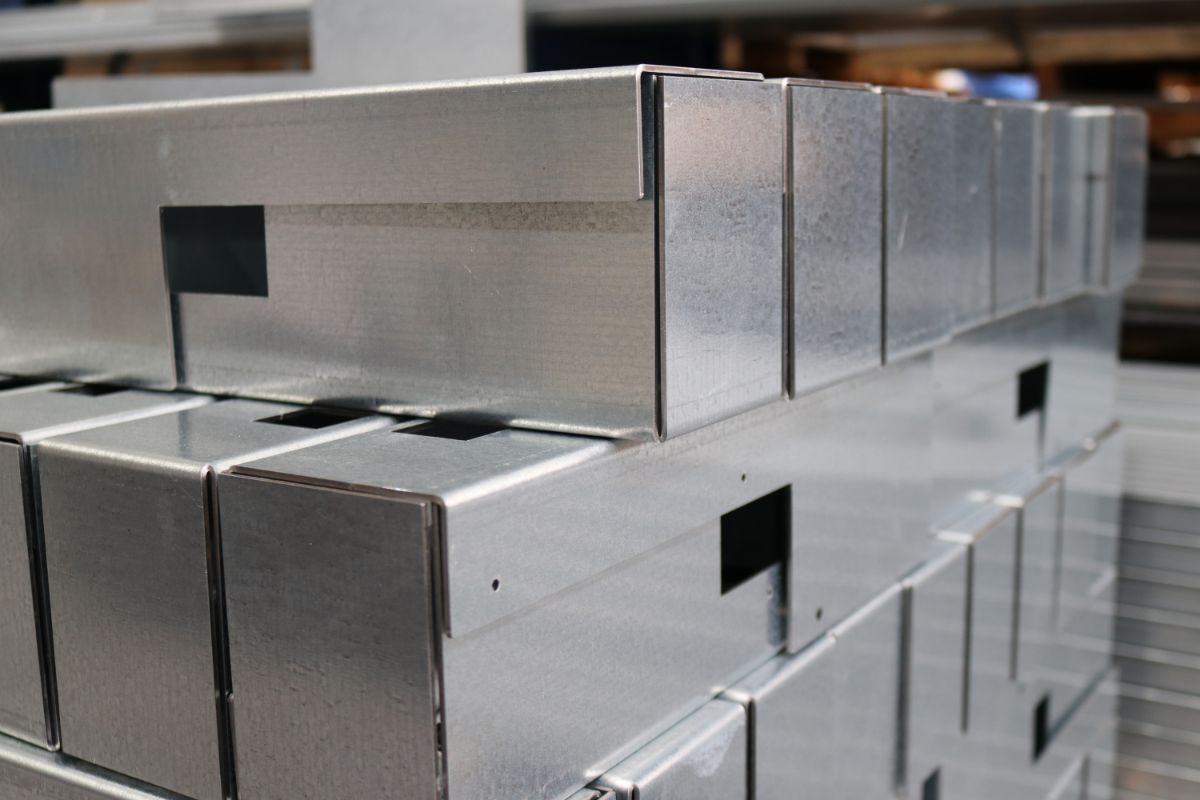

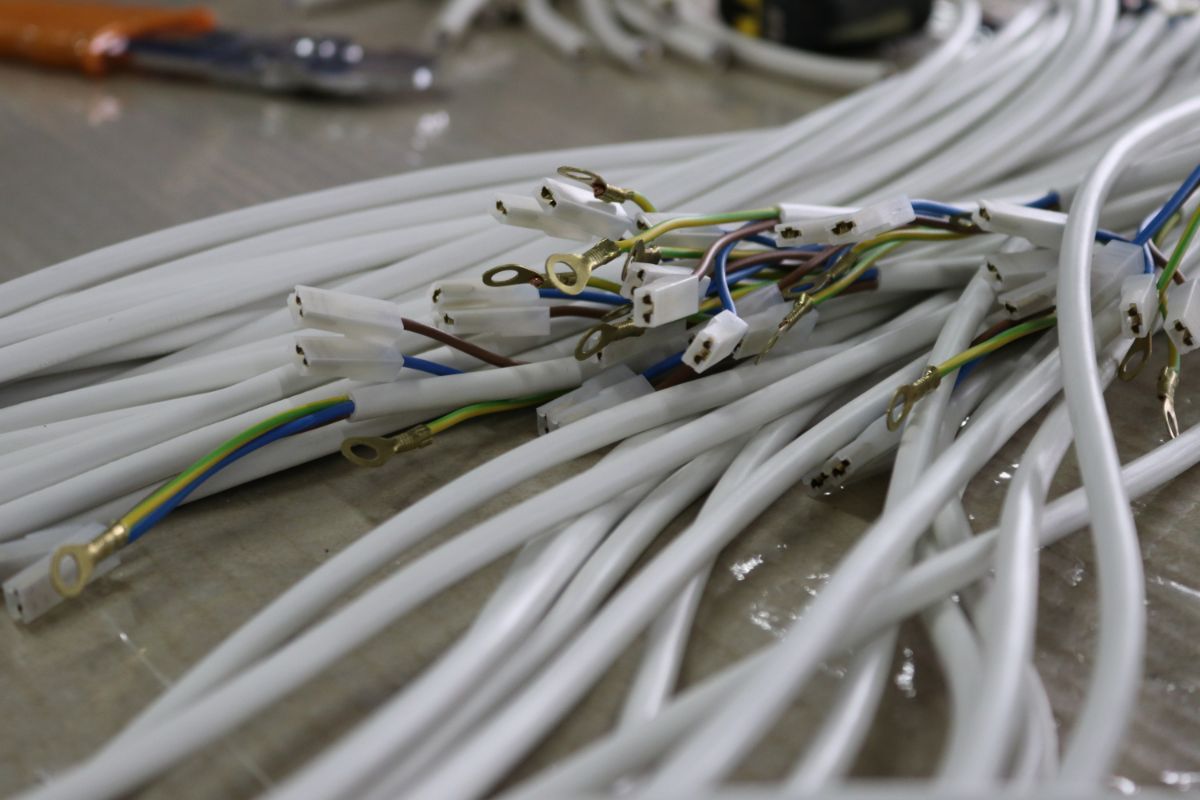

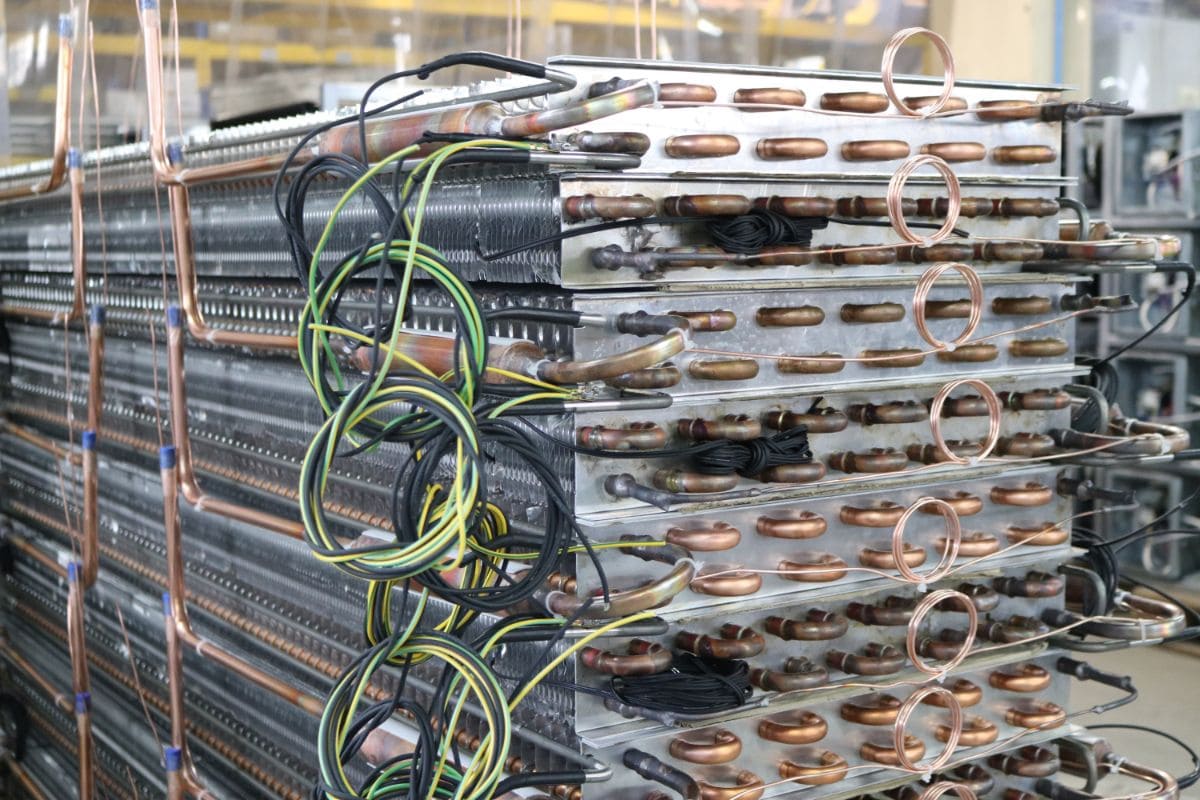

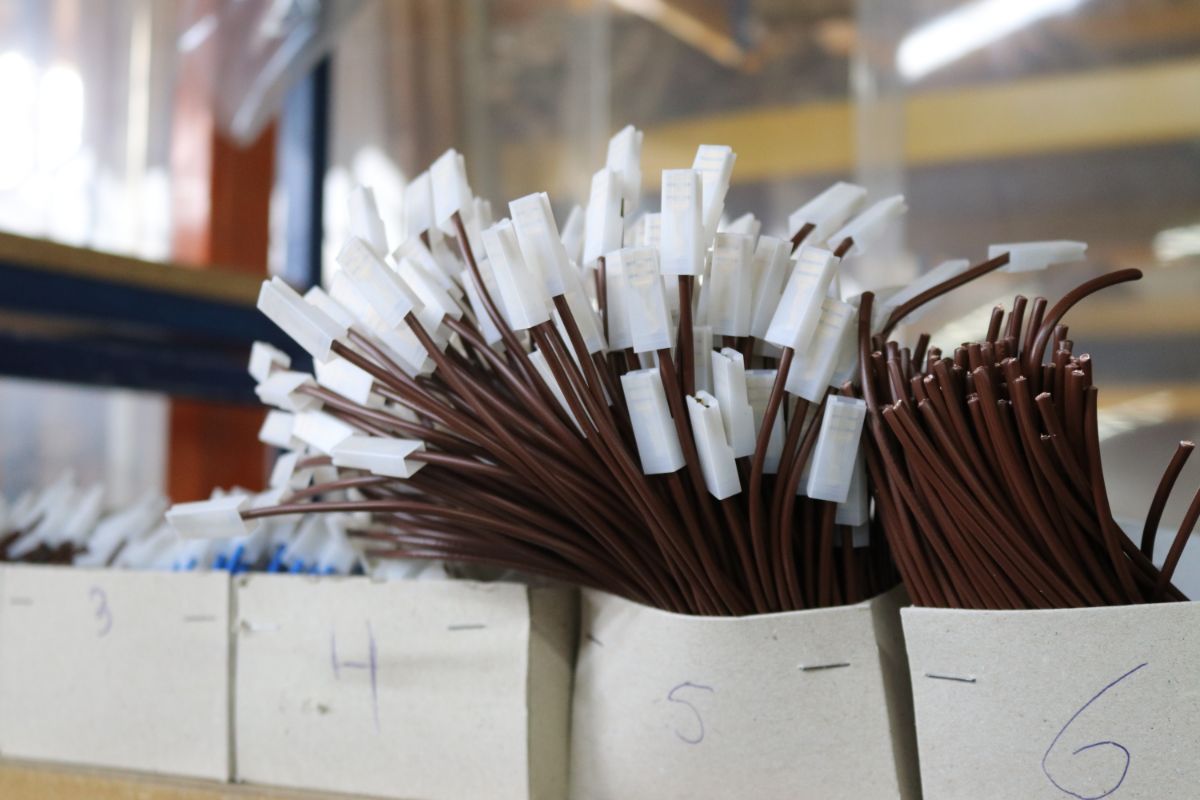

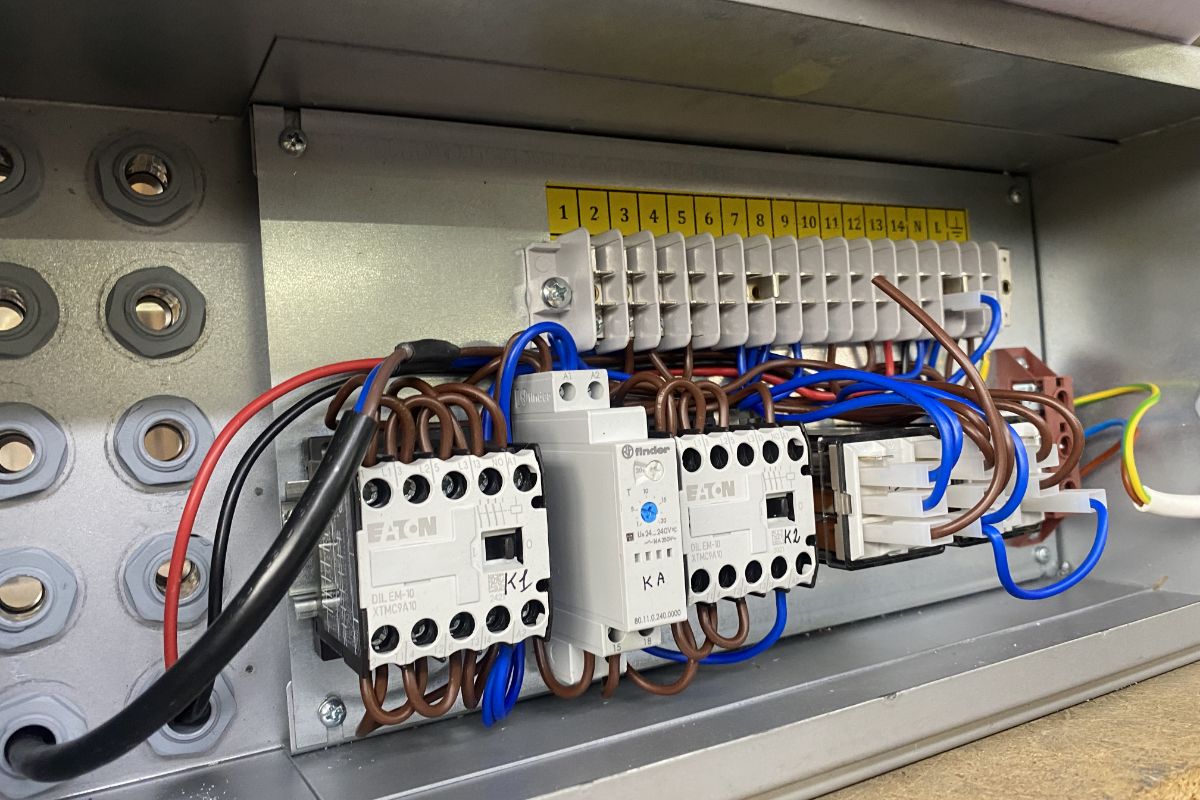

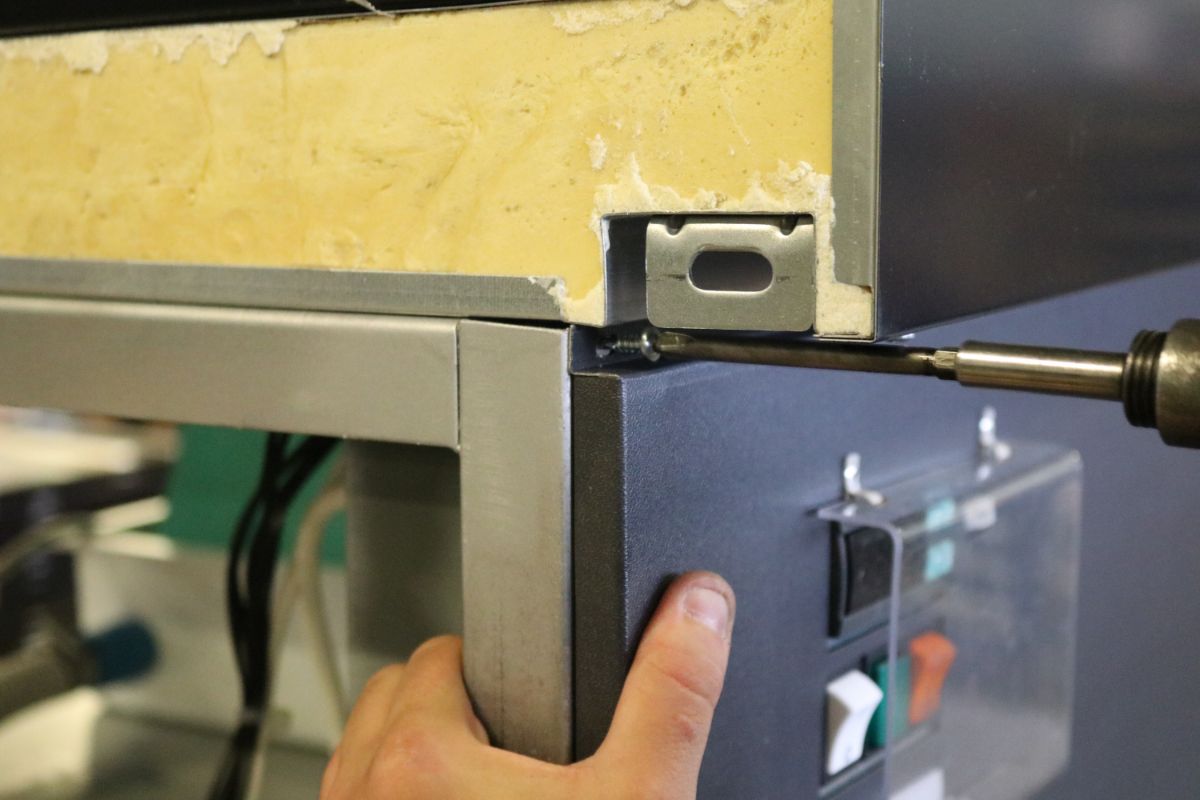

One of Hydracooling’s strong pillars is based on the preparation section, thanks to its integrated traceability system.

The traceability of the main components of the equipment throughout their life cycle has an essential role in enhancing efficiency by:

- Anticipating future actions;

- Generating continuous improvement actions;

- Automating the production cycle;

- Ensuring the quality and added value of the products.

The possibility of permanent consultation in digital format of all the documentation serves as a support for this team of professionals with unquestionable know-how.

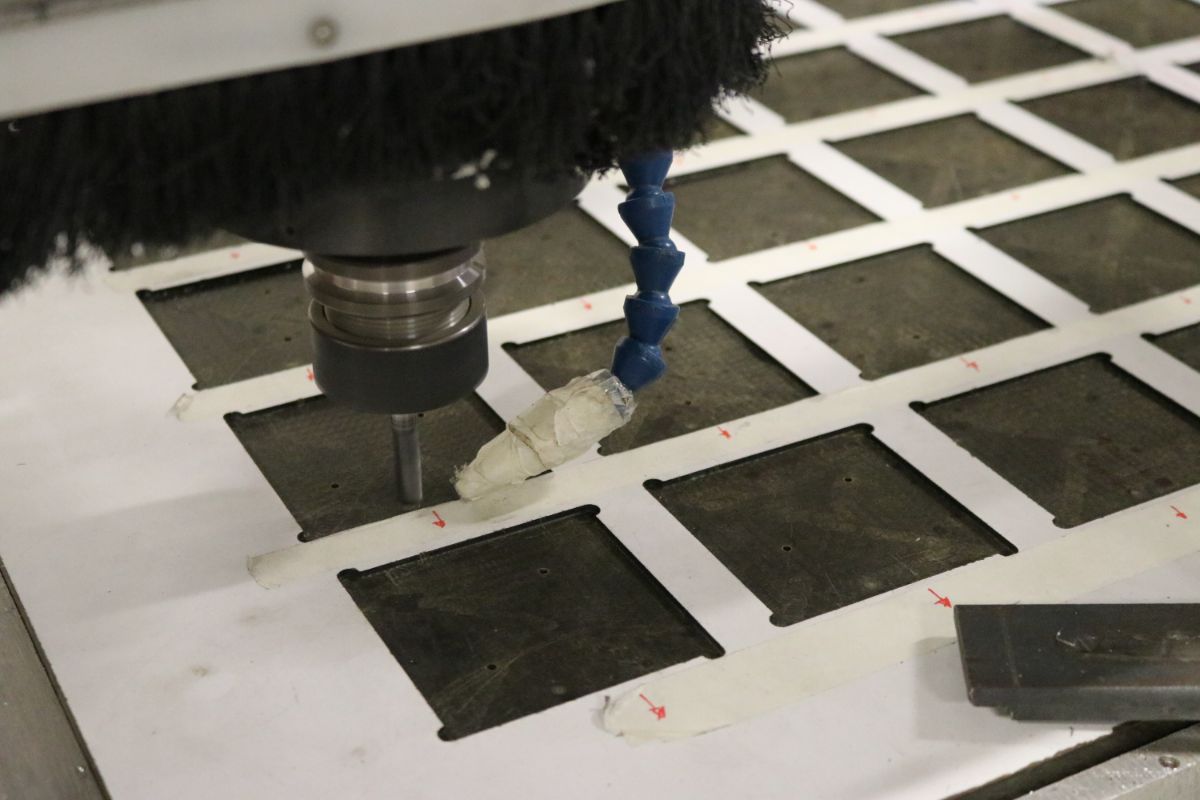

Thermoforming & Injection

With equipment adapted to the needs, combined with the knowledge of its team, Hydracooling masters the transformation processes transversally.

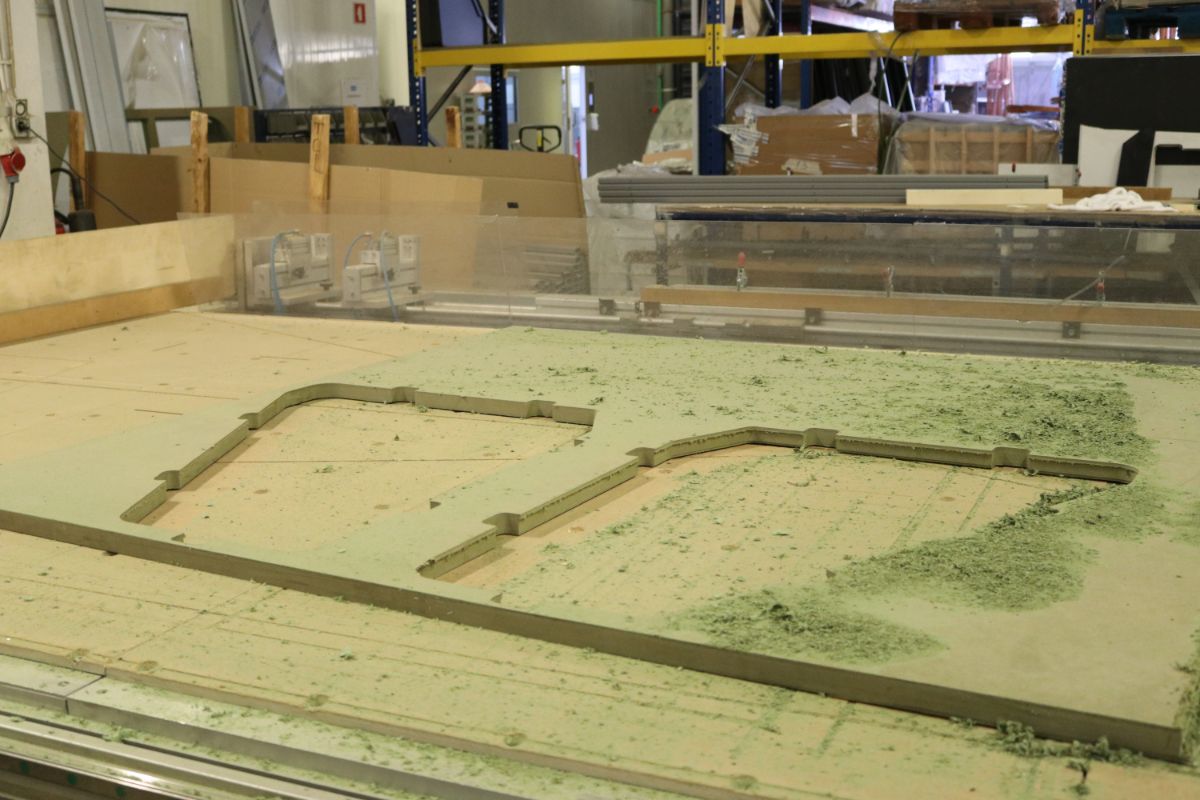

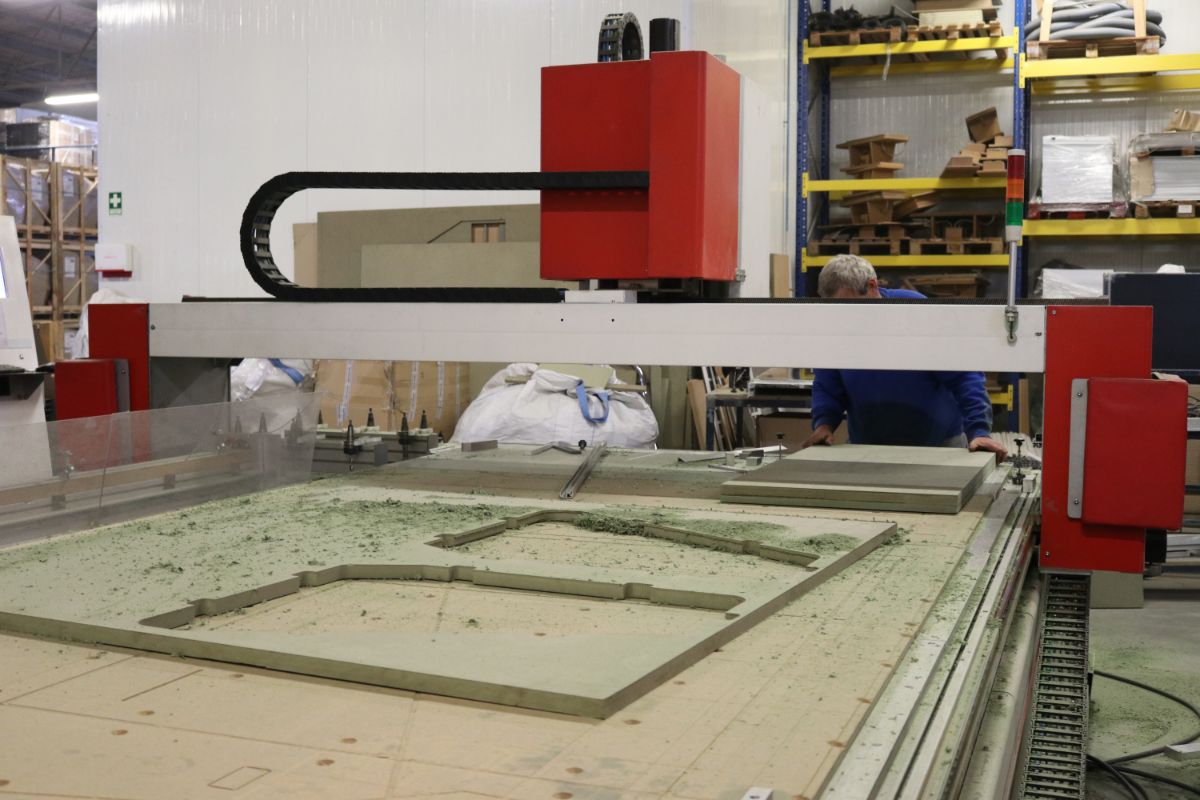

For vacuum thermoforming, the molds owned by Hydracooling allow the control of the qualitative process. The feedback mechanism of the molds is also provided internally, using the CNC machine, used for the cutting of aluminum and wood for the molds mainly, aiming at adaptability for future projects.

The injection section has forming units adapted to each model with semi-automatic loading and unloading, avoiding incidents and increasing efficiency.

In order to reduce the ecological footprint, Hydracooling uses water-based expanded polyurethane injection to ensure better insulation with a lower environmental impact.

Due to the dimensions of the chassis and the successive process to the chain, the chassis benefit from special logistics, which ensures the correct storage and the fast supply of the assembly line.

Assembly Line

The assembly line facilitates the delivery of the equipment thanks to a serial manufacturing scheme with a linear configuration. Hydracooling has several assembly lines, one dedicated to R290 gas and a second one, soon to be implemented, allowing large-scale production.

With lifting platforms to simplify the work of each station, the workflow is optimized and continuous, ensuring proper planning and deliveries on time.

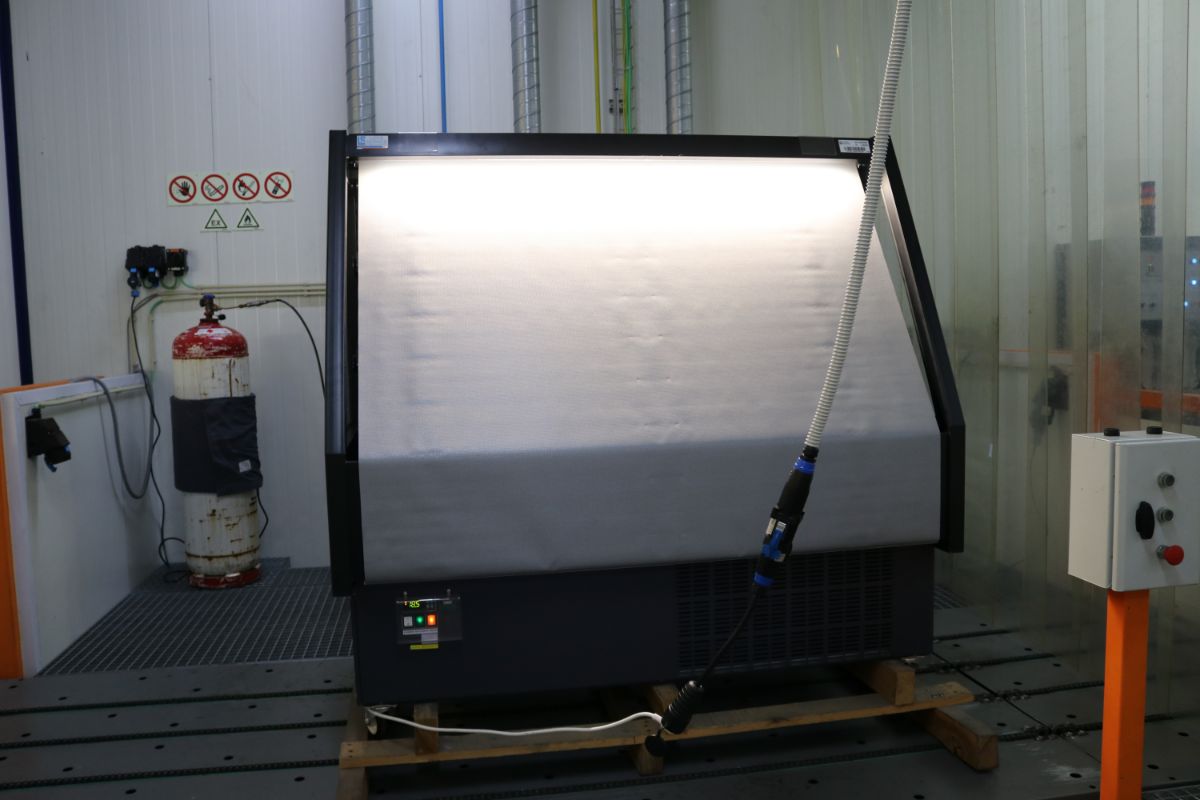

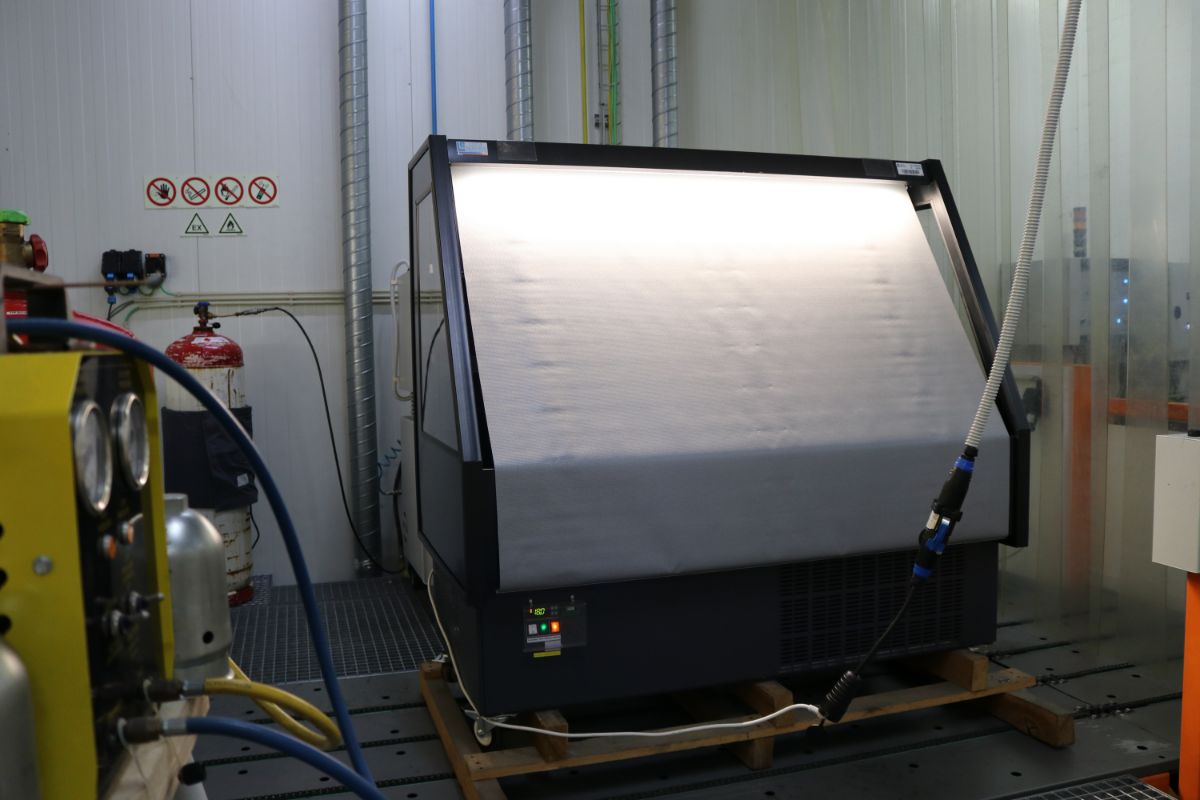

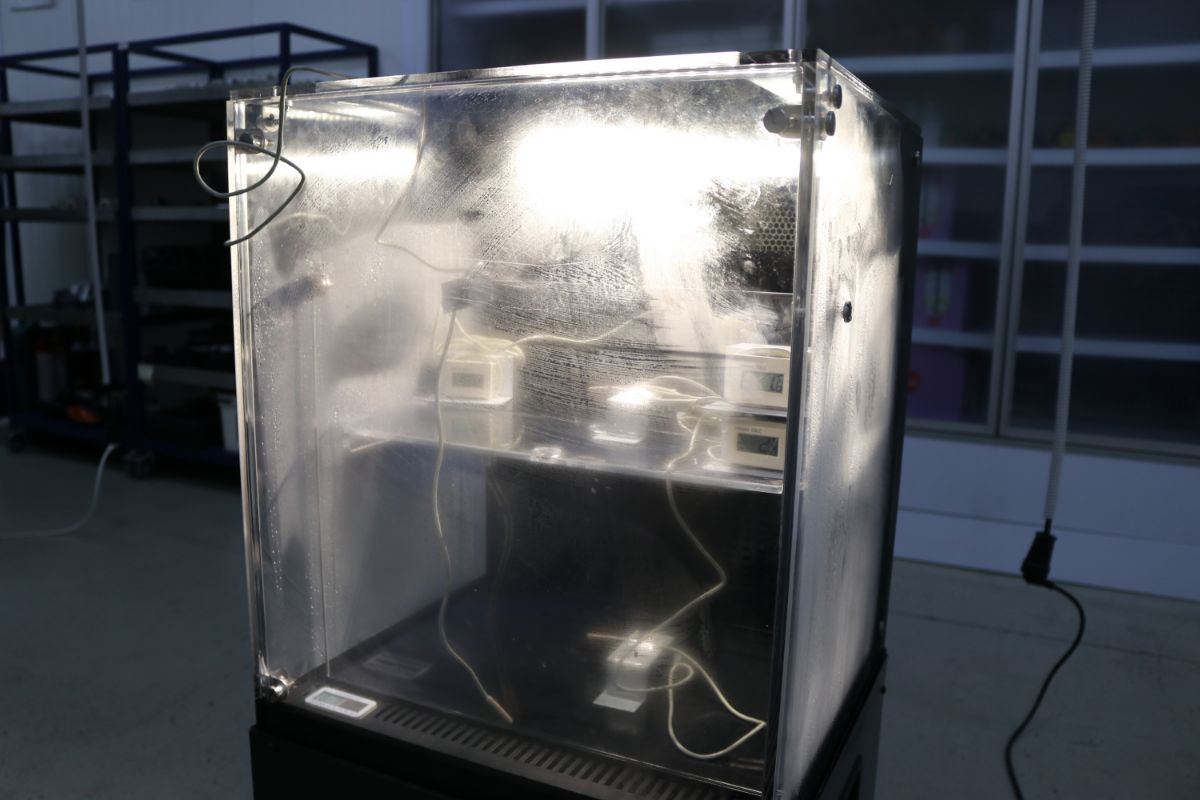

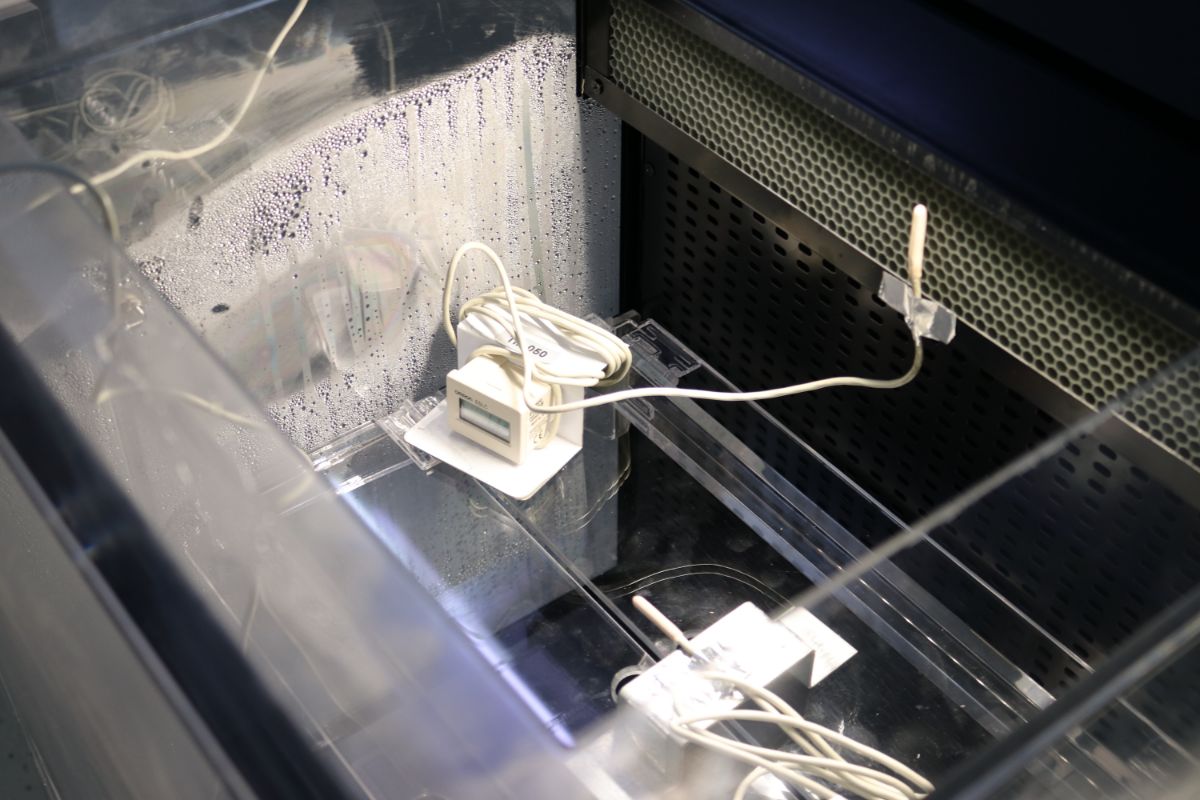

Ensuring the quality of the equipment is essential, once the pre-vacuum is completed and the passage through the R290 gas cell (Atex) carried out, all the equipment goes through the verification tunnel to perform:

- A series of electrical tests;

- A Check and evaluation of the operation of the equipment for at least 2 hours, subject to conditions inherent to its climate class (25ºC and 60% relative humidity).

The purpose of this differential process is to confirm that all equipment sent to the customer meets the required technical requirements, thus ensuring a higher level of quality – Hydracooling Quality.

Logistics

The Logistics unit facilitates the supply of the remaining sections, whether with internally or externally manufactured components. At the operational level, Hydracoolings logistics is based on 4 concepts:

Supply logistics – resources management through storage and flow management, thus meeting all Hydracooling needs.

Production Logistics – intimately linked to Production planning, Production Logistics ensures that all workstations are supplied, optimizing storage capacity through the inventory management system with identified shelves.

Distribution Logistics – involves the management of equipment outputs, managing not only the shipments and associated documentation, but also the type of packaging, since the customer can choose between cardboard packaging, crate or treated pine.

Reverse logistics – Residual materials are unavoidable in the manufacturing process. This is why reverse logistics have become fundamental to ensure the collection and recycling of cardboard, plastic and metal.

Production & Purchasing

Agile and facilitated management through continuous monitoring of equipment and components in the production process through ERP. Implementation of technological solutions for workshop management, planned for 2023, meeting the needs of superior management, with the clear objective of managing and controlling production and operations in real time according to current and evolving engineering and quality requirements.

Combining productive management and logistics management, the mission of purchasing is to manage more than 160 suppliers, with the aim of finding competitive prices, quality and confidence in terms of delivery.

One of the principles of our supply chain is trust. We rely on the code of conduct and all our suppliers are periodically subject to an evaluation for management in symbiosis with the company’s social responsibility.

Management by ERP and validation by inventory monitoring allow the development and implementation of an adequate purchasing policy.

R&D

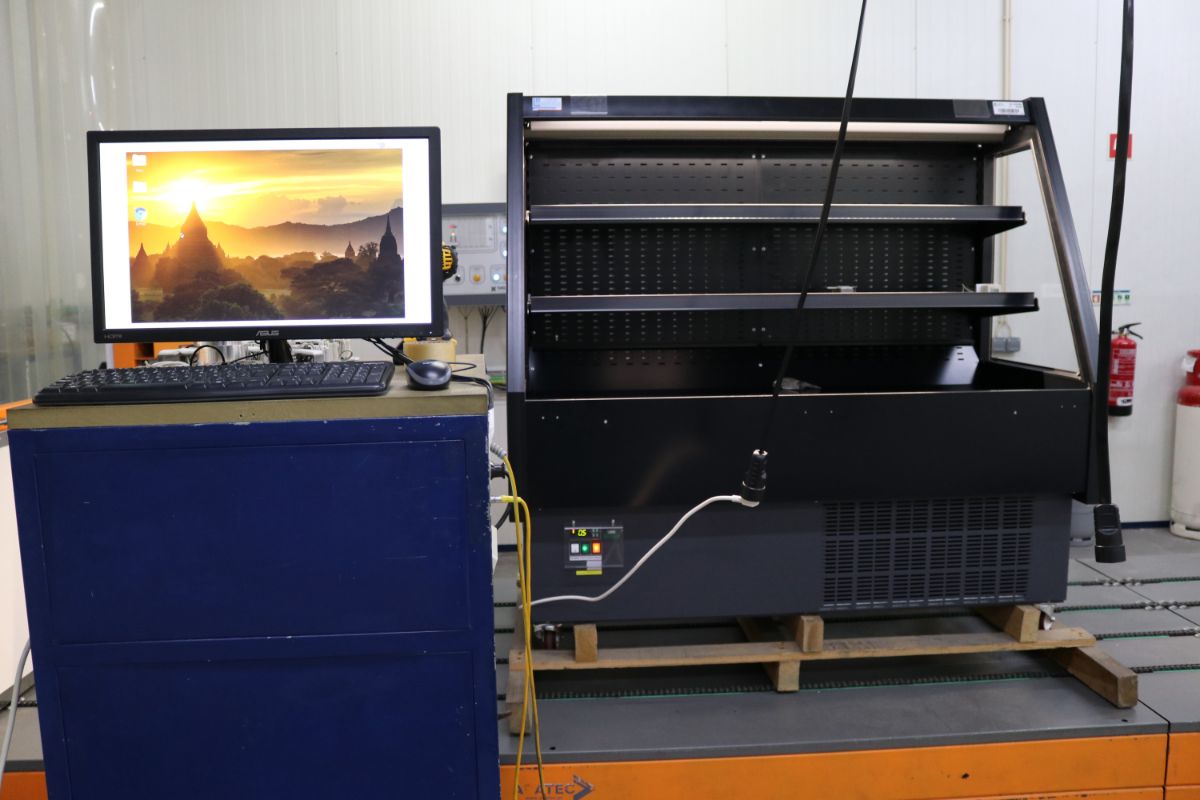

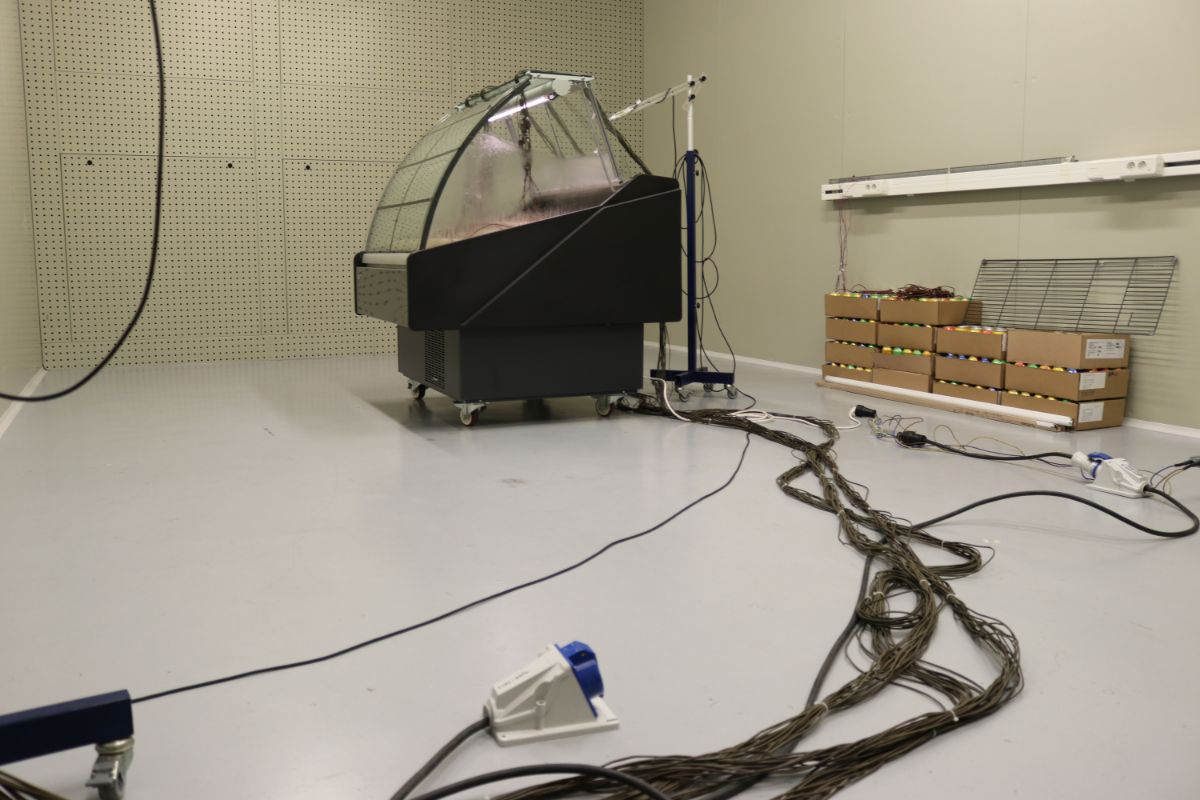

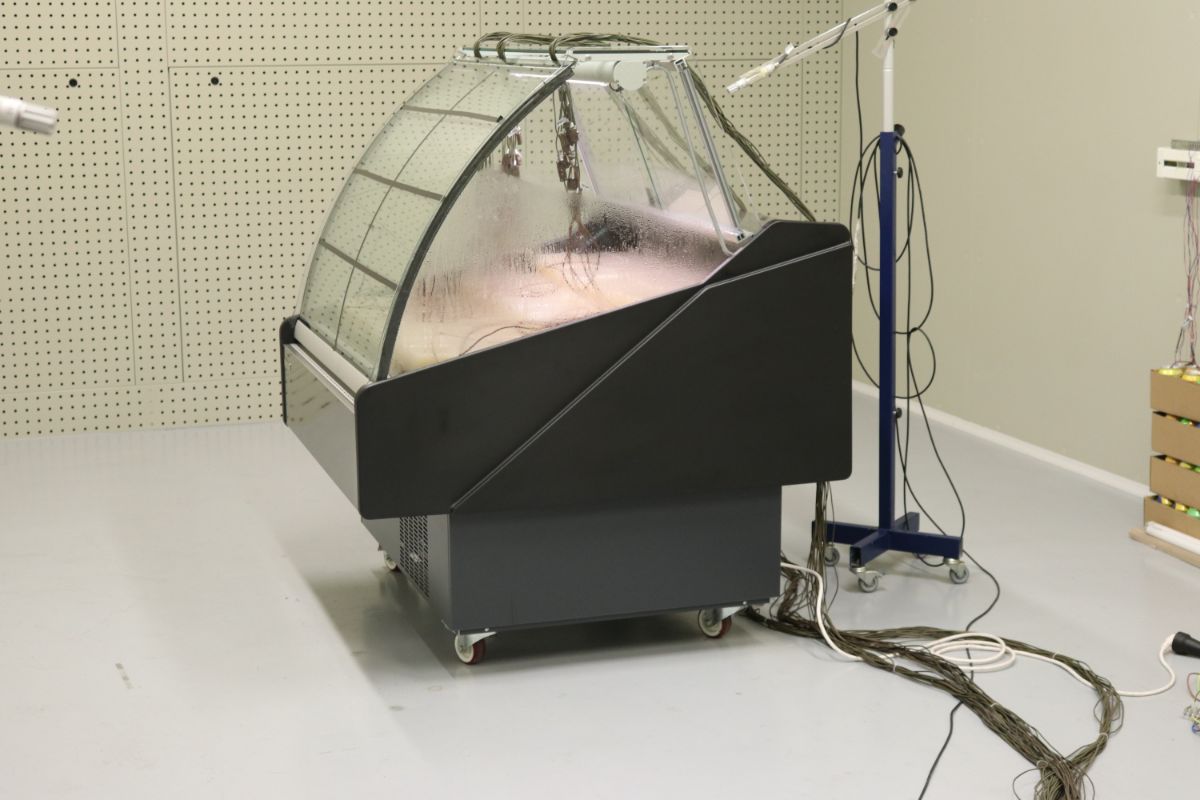

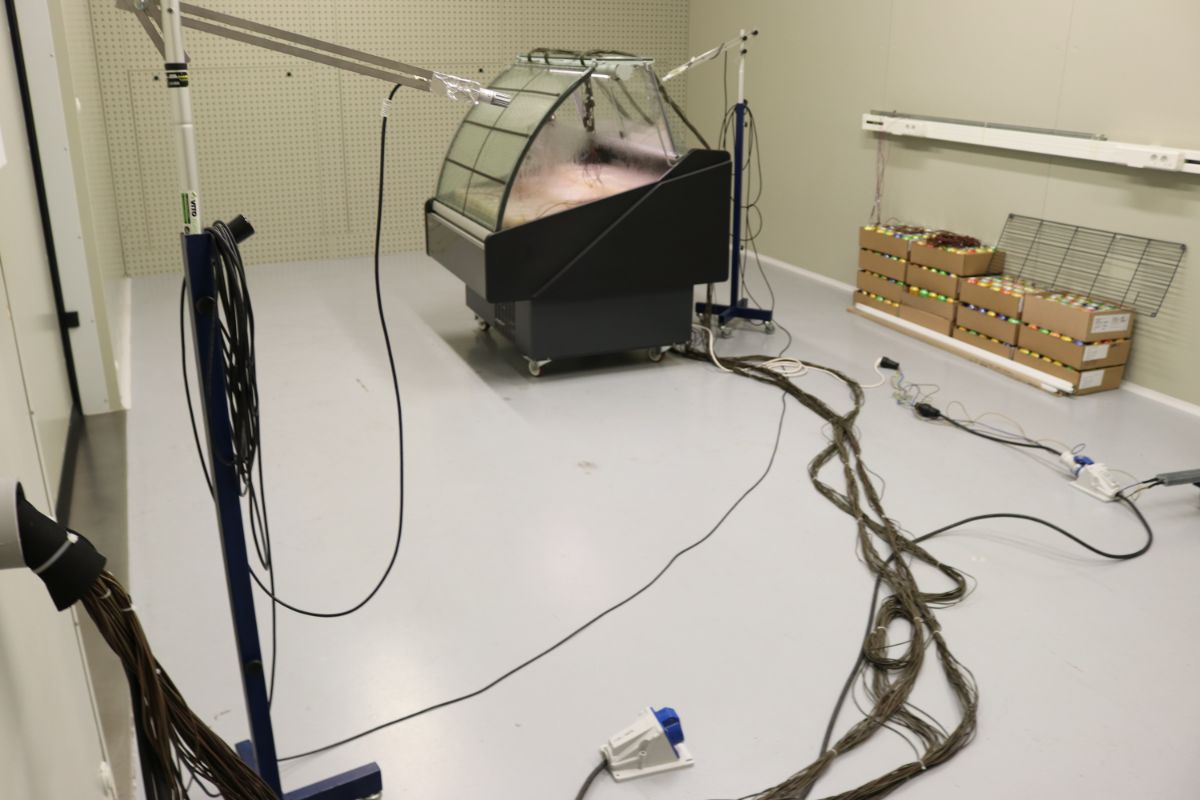

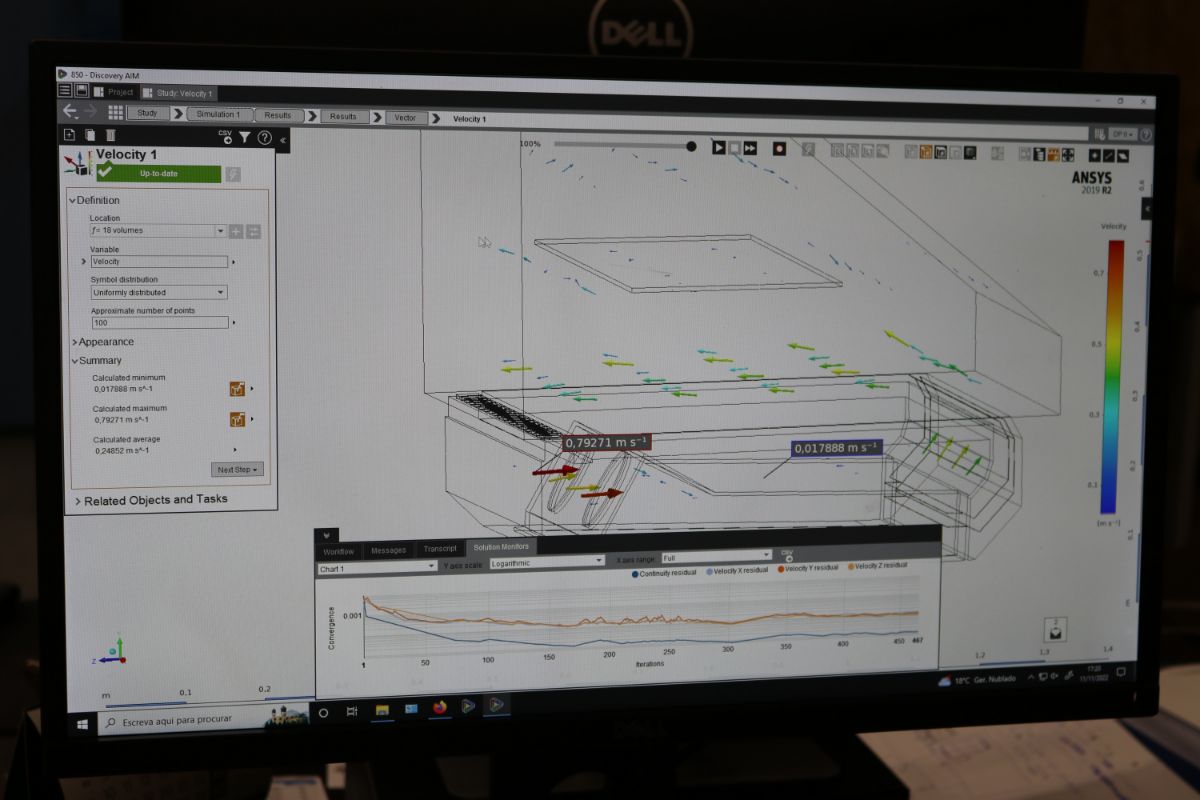

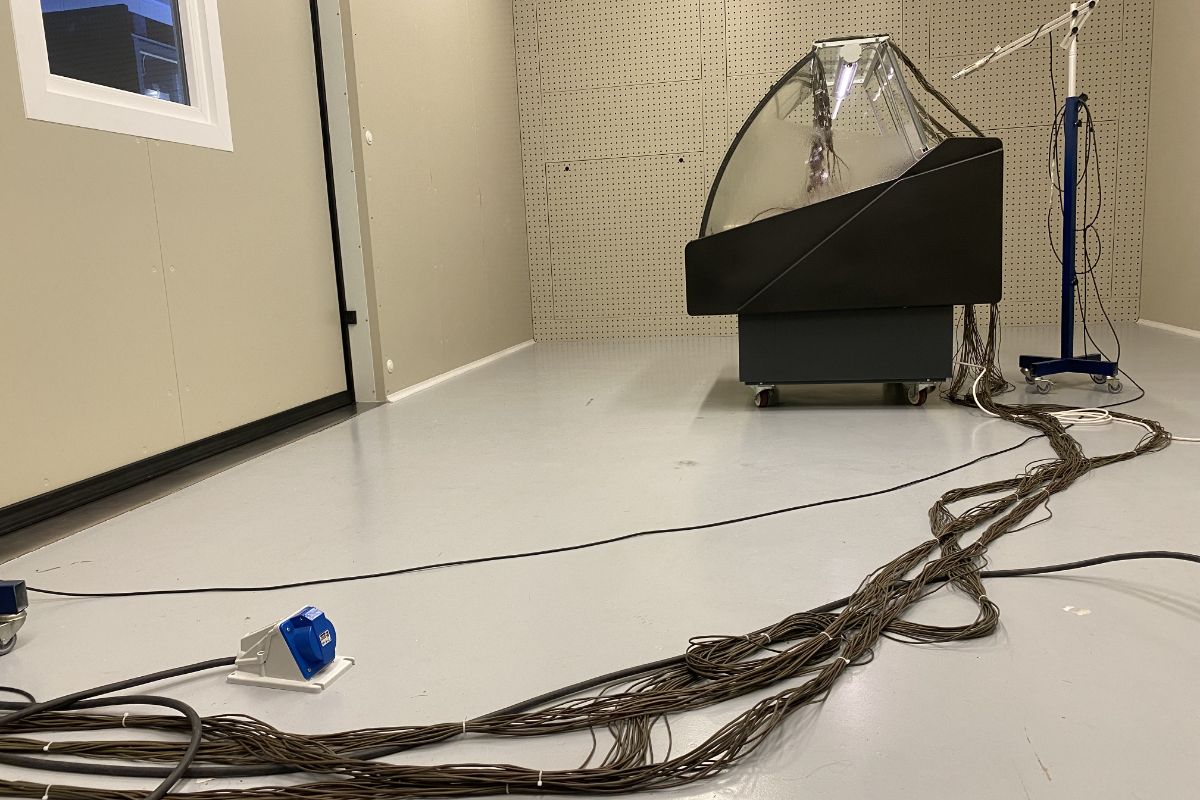

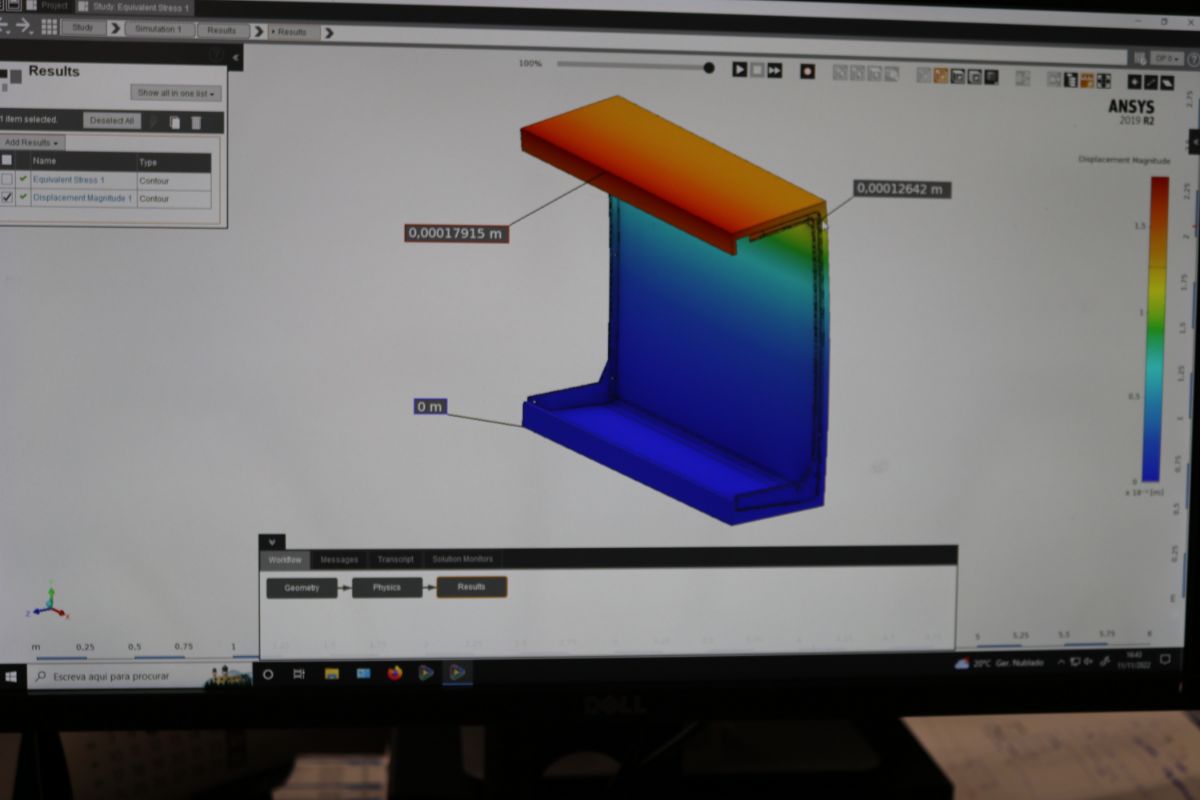

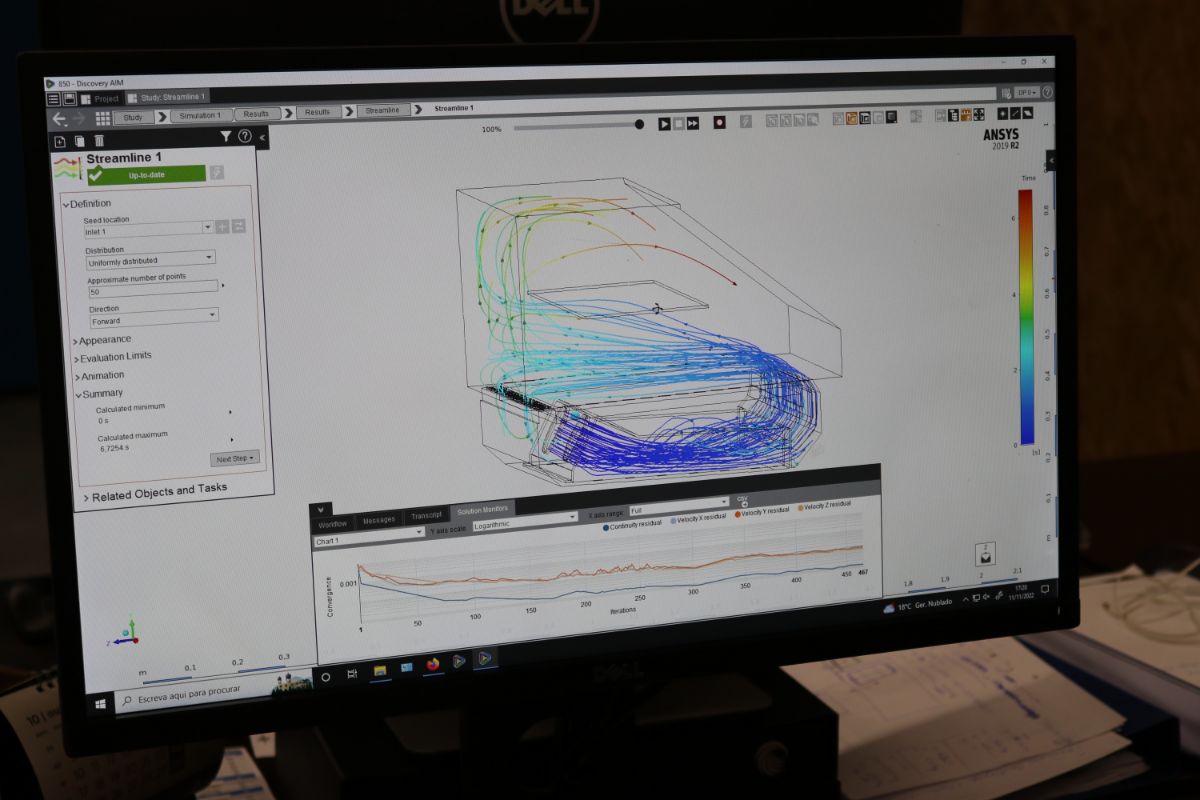

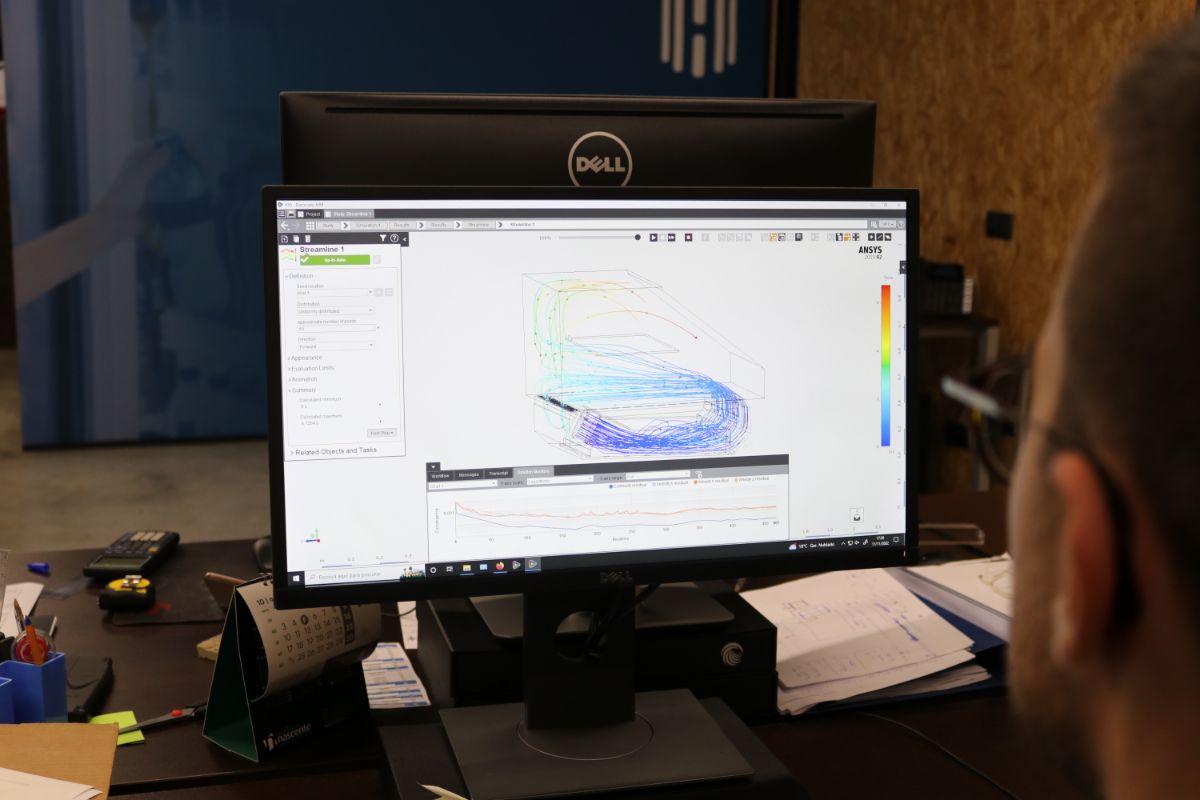

With a qualified and young team, and modern means for design, Hydracooling is proud of its pioneering laboratory facilities in the country.

The continuous improvement of designs and the consequent increase in the quality of equipment through tests are essential. The development of new solutions and applications allows a continuous innovative process, guaranteeing a value contribution to the final consumer.

Innovation is one of the fundamental pillars, seeking to probe market trends and create our own lines by meeting current needs and anticipating future wishes and shortages.

Administrative & Commercial

Hydracooling’s complex process management also involves:

HR – The Human Resources department is responsible for the most valuable Hydracooling asset: its employees.

It is a sector that intervenes not only in the treatment of wages or absences, but mainly in the development and management of human capital, in order to ensure well-being, optimization of working conditions and team spirit, one of the Hydracooling values.

Finance Department – Supports and validates all international economic and tax operations of the company. Keeping track of the figures, this department is always up to date with regards to the national and international economy and the legislation of our industry.

Thanks to our know-how, we will seek to reconcile Hydracooling’s financial objectives with a reduction in costs in order to meet productive and commercial objectives. It is the department that interprets the actions of other departments in a quantitative way and seeks points for improvement so that we can continue to offer the best we have.

Fundamental financial management planning is developed in close connection with the management team as it is the only way to allow for continued growth.

Commercial & Marketing – Work based on human relations with personalized follow-up. The transactional journey is really only worth it that way. What’s really important is the individual. That’s why Hydracooling focuses on connections, working as individuals for individuals.

We seek to understand how our equipments and/or complements can meet the needs of our partners, ensuring that through our solutions there has been a real contribution of added value to our client’s business.

Contacts

Address

Parque Industrial de Guimarães1ª Fase - Pavilhão G15

4805-661 Guimarães

Portugal

Receive our news

This site is protected by reCAPTCHA and the GooglePrivacy Policy and Terms of Service apply.